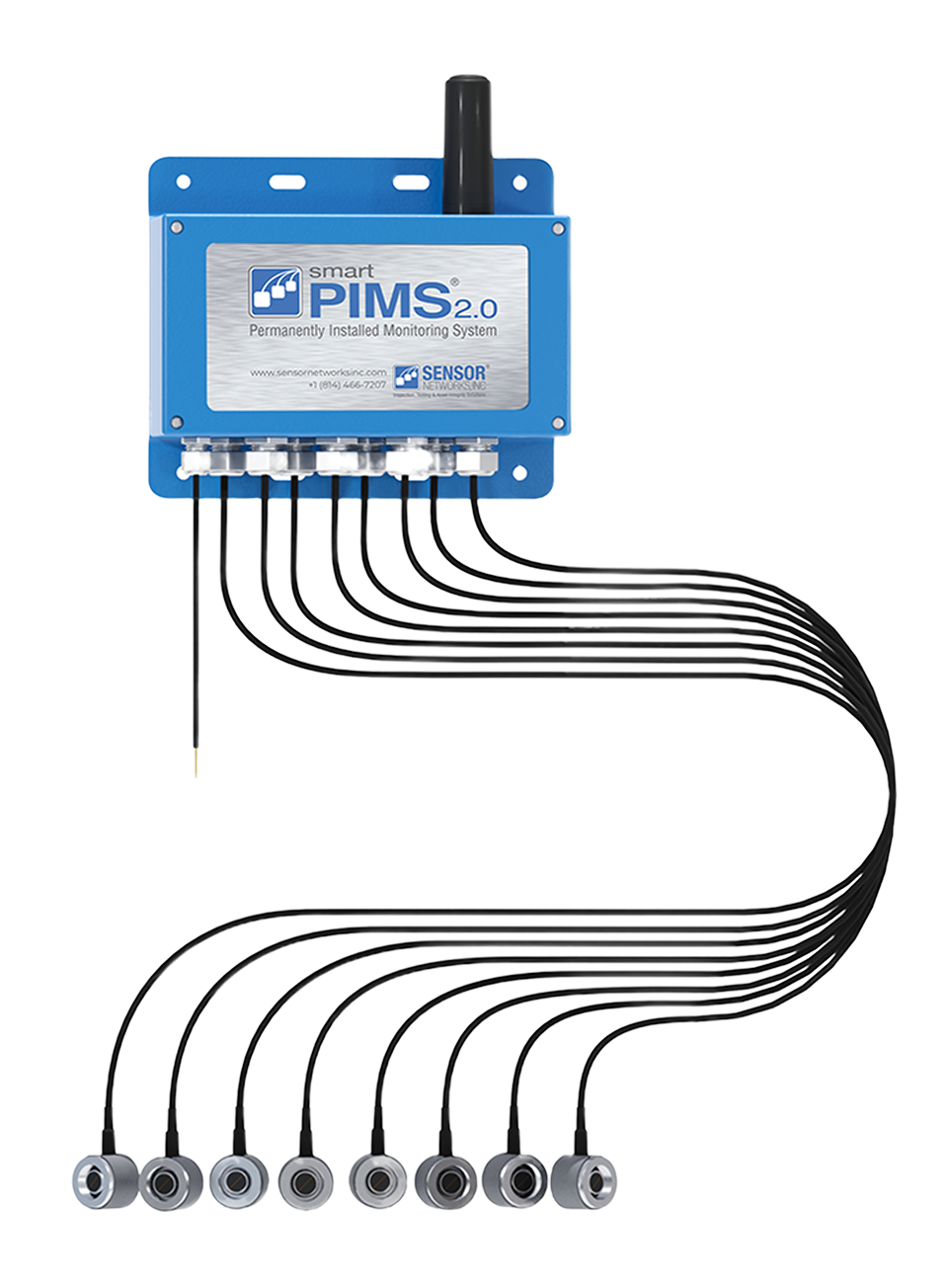

SmartPIMS 2.0

Installed UT Sensor

An advanced, non-intrusive ultrasonic corrosion/erosion monitoring system designed for critical assets. It supports up to 16 ultrasonic sensors for comprehensive coverage, with data collected via manual or cellular methods and analysed in webPIMS™ software for trending and databasing.

Fast & Consistent Data Readings

Applications where frequent data is required to monitor corrosion/erosion rate issues.

Short term or long-term corrosion monitoring

smartPIMS can be installed permanently or temporarily, allowing for long- or short-term data collection and monitoring.

Automatic & hands-free monitoring

smartPIMS sensors are designed to take thickness readings at user-defined intervals and gives operators the ability to collect their data without the need for in-person inspection.

Easy Installations

With magnetic and clamp-style attachment options available, smartPIMS are easy to install – without sacrificing performance and accuracy.

Multi-point monitoring

smartPIMS multi-point monitoring systems can be used to gain increased coverage of known critical and problematic areas.

3 Connectivity Options

Cellular

smartPIMS 2.0 Cellular system is equipped with an onboard battery and an LTE-M/Cat M1 cellular modem for data transfer to the internet via cellular data connectivity. The system can be programmed to obtain thickness values at user defined time intervals and transmit data to SNI webPIMS backend application for databasing, trending, and analysis.

- Cellularly transmits data to webPIMS™

- Operates on battery (5-7 years at 1 reading/day)

- Maintains 1 mil (0.001″ /0.025mm) precision for minimum wall thickness of 0.040″ (1mm) for duals and 0.125″ (3.2mm) for delay-line

- Thickness data collection set at user-defined intervals

Datalogger

Datalogger is equipped with an onboard battery and system memory enabling the storage of up to 3,000 thickness readings. The system can be programmed to obtain data on a user-defined schedule and store all the data onboard. Users connect to the unit via DIU adapter and table/PC using dataPIMS software. Data is downloaded and available in XML or CSV (Excel) file format or uploaded to SNI webPIMS backend software for databasing, trending, and analysis.

Collects and stores data at a safe and convenient collection location

dataPIMS software outputs data to XML or CSV file, or can be uploaded to webPIMS

Maintains 1 mil (0.001″ /0.025mm) precision for minimum wall thickness of 0.040″ (1mm) for duals and 0.125″ (3.2mm) for delay-line

Thickness data collection set at user-defined intervals

Modbus

Modbus system connects directly to a PC or laptop to take on-demand thickness readings, store them on the local PC in SNI dataPIMS software and optionally upload to SNI webPIMS backend application for databasing, trending, and analysis

The system can also be wired directly into a SCADA/DCS system for polling at any user-defined schedule. New data can be read via standard Modbus commands and displayed on local consoles or ported to company backend management systems.

- Connects via Modbus (RS-485) to table/PC or SCADA/DCS

- dataPIMS software outputs data to XML or CSV file, or can be uploaded to webPIMS

- Maintains 1 mil (0.001″ /0.025mm) precision for minimum wall thickness of 0.040″ (1mm) for duals and 0.125″ (3.2mm) for delay-line

- Ability to hardwire directly into a plant/facilities control system

THE NEW SOLUTION TO NON-INTRUSIVE CORROSION & EROSION MANAGEMENT

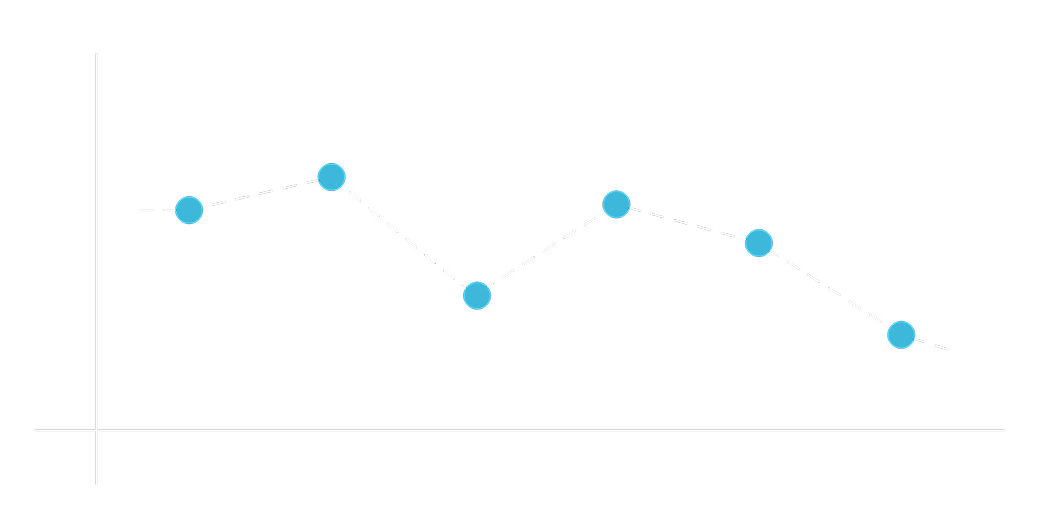

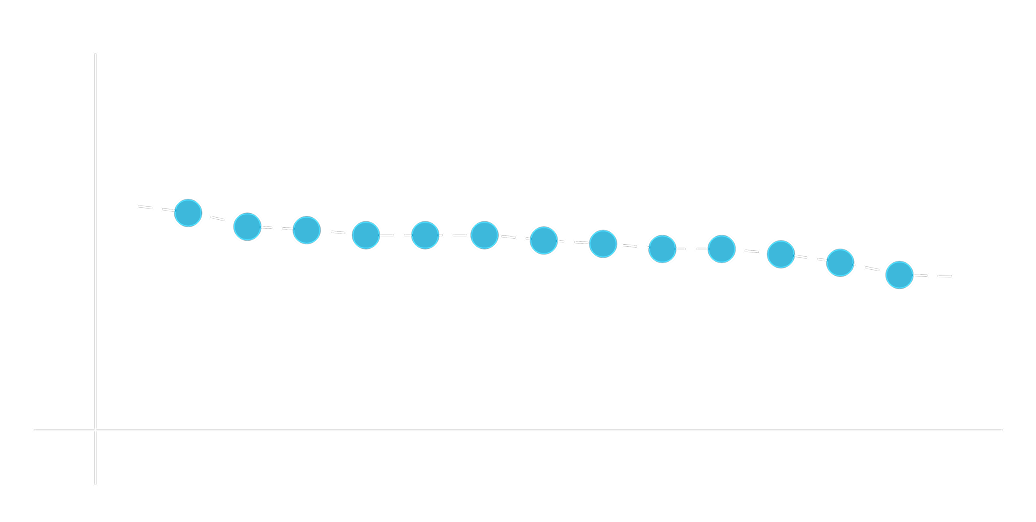

Our line of non-destructive corrosion/erosion sensors provide an advanced inspection method; Monitoring. With corrosion and erosion monitoring, asset owners are able to gain further insight into their assets by taking frequent and consistent thickness measurements, without the need for manual inspection methods. With higher quality and quantity data, owners and operators are able to analyse, trend, and correlate corrosion/erosion rates with their processes and make necessary adjustments to mitigate potential problems.

INSPECTION vs. MONITORING

Q&A

SNI's Permanently Installed UT Corrosion Monitoring Sensors combine the proven technique of Ultrasound Thickness Gauging with cutting-edge Internet of Things (IoT) technology. This enables continuous monitoring of wall thickness in critical infrastructure, providing real-time data on corrosion and erosion-related wall loss.

Both the SmartPIMS and MicroPIMS offer an ultra-high temperature option, featuring a single-element delay-line, designed for installation on surfaces with temperatures up to 500°C.

The SmartPIMS and MicroPIMS systems utilize a specialized epoxy as a couplant, effective for surface temperatures up to 80°C. Once cured, the epoxy remains in place, providing a permanent coupling between the sensor and the surface. For high-temperature applications, a malleable silver foil is used, clamped between the sensor and the surface. This silver foil ensures optimal contact for the proper propagation of ultrasound energy.

Request a Demo

Would love to see a demo? Share your contact details with us and our team will reach out to you shortly.