microPIMS

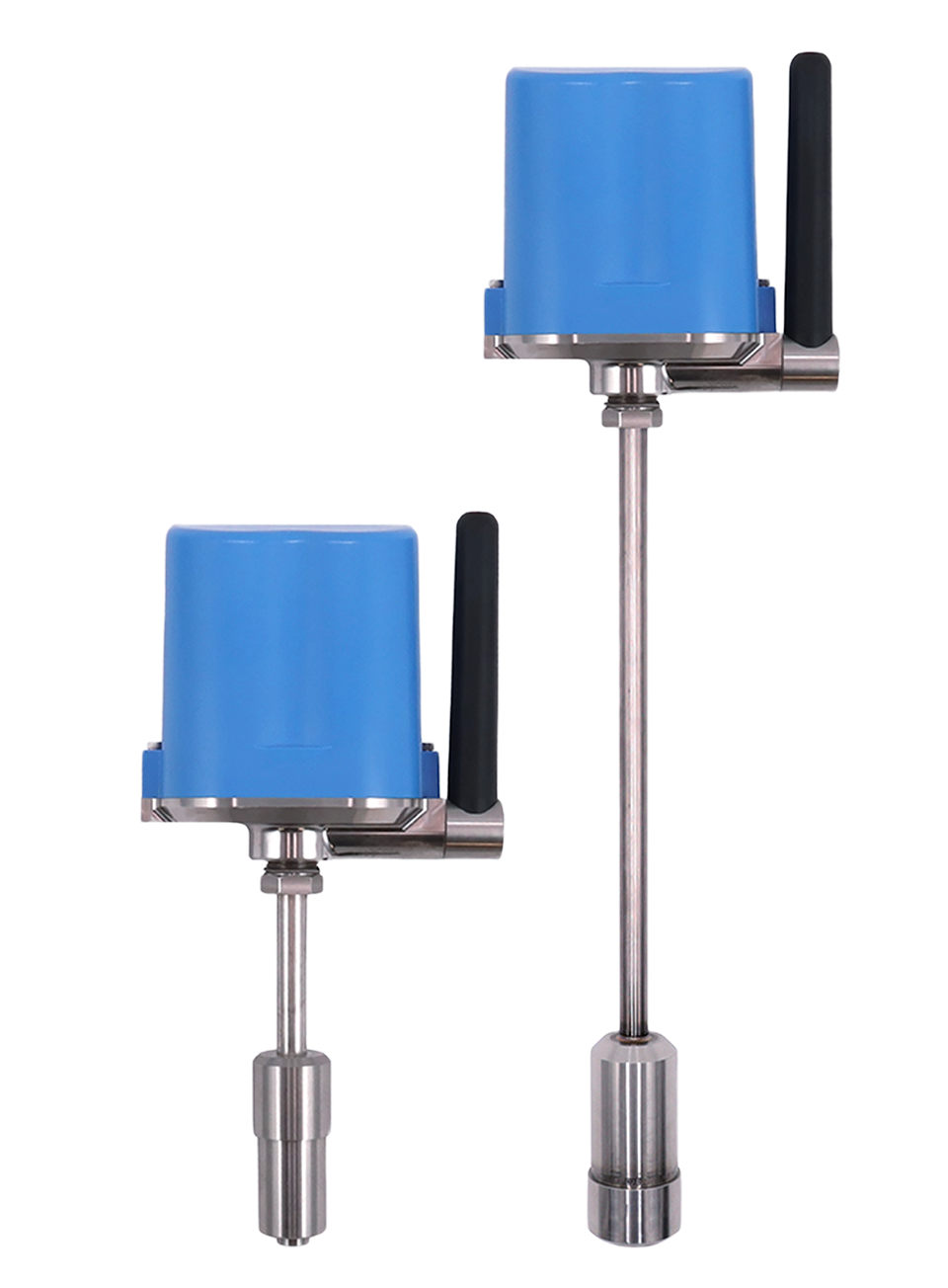

Installed UT Sensor

A wireless, non-intrusive ultrasonic corrosion/erosion monitoring system. With long-range sub-GHz wireless connectivity and long-life batteries, it sends user-defined readings to the cloud-based or on-premises webPIMS™ software for analysis and trending.

Fast & Consistent Data Readings

Applications where frequent data is required to monitor corrosion/erosion rate issues.

Short term or long-term corrosion monitoring

microPIMS gives short-term or long-term corrosion rate data that is needed to monitor crude-slate changes or to correlate operational system updates.

Monitoring that is automatic & hands-free

Once installed, microPIMS can take thickness readings at user-defined intervals, allowing for more frequent data without the cost of manual inspections.

Easy Installations

With magnetic and clamp-style attachment options available, microPIMS are easy to install – without sacrificing performance and accuracy.

Multi-point monitoring

Each gateway can connect up to 1,000 microPIMS, allowing full coverage of targeted areas in a facility. Each microPIMS communicates directly with the gateway reducing battery drain.

THE NEW SOLUTION TO NON-INTRUSIVE CORROSION & EROSION MONITORING

Measuring corrosion and erosion rates is an important part to keeping potential problems from becoming disastrous realities. Over the last 70 years, ultrasonic non-destructive testing (NDT) has become a proven, established, and refined technology. Advances in microelectronics, software, wireless communications and the “internet of things” have made “installed ultrasound” an extremely attractive and cost-effective solution. microPIMS was designed by our engineers to give you all of the necessary tools to collect frequent data, without the need for manual inspections.

Q&A

SNI's Permanently Installed UT Corrosion Monitoring Sensors combine the proven technique of Ultrasound Thickness Gauging with cutting-edge Internet of Things (IoT) technology. This enables continuous monitoring of wall thickness in critical infrastructure, providing real-time data on corrosion and erosion-related wall loss.

Both the SmartPIMS and MicroPIMS offer an ultra-high temperature option, featuring a single-element delay-line, designed for installation on surfaces with temperatures up to 500°C.

The SmartPIMS and MicroPIMS systems utilize a specialized epoxy as a couplant, effective for surface temperatures up to 80°C. Once cured, the epoxy remains in place, providing a permanent coupling between the sensor and the surface. For high-temperature applications, a malleable silver foil is used, clamped between the sensor and the surface. This silver foil ensures optimal contact for the proper propagation of ultrasound energy.

Request a Demo

Would love to see a demo? Share your contact details with us and our team will reach out to you shortly.