webPIMS

Software

A cloud-based corrosion/erosion data management software that enables users to efficiently analyse, set alarms, trend, map, export, and report metal-loss data and rates.

Custom Alarms

Create custom alarms to alert you based on corrosion rate thickness value.

Temperature adjusted

All thickness readings are temperature adjusted to ensure consistent and accurate data regardless of process changes, start-up, shut down, or upsets.

Effortless data export

Quickly and easily export data to a .xml or .csv file for reporting or mass export to historians/IDMS.

Trending

View and analyse historical data and compare to your operating schedule to optimize process control.

Optional On-Prem solution

For those who want to keep their data off the cloud, the On-Prem webPIMS data management system provides a local self-contained / in-the-fence system.

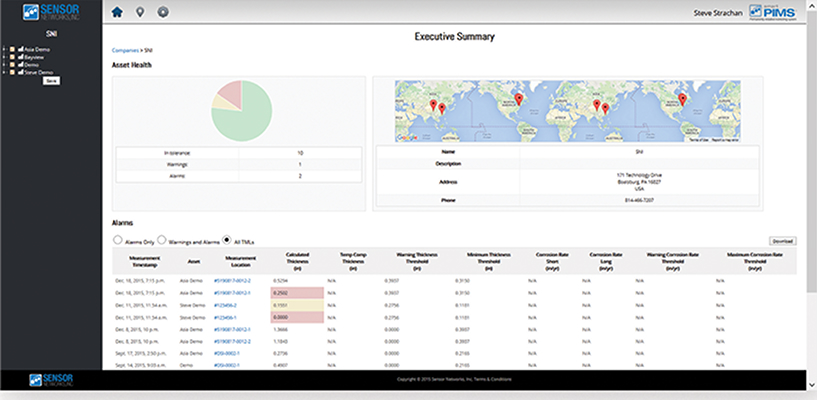

Home page screen showing enterprise-wide macro view, including pie chart with sensor location, status, GPS and latest readings of all sensors.

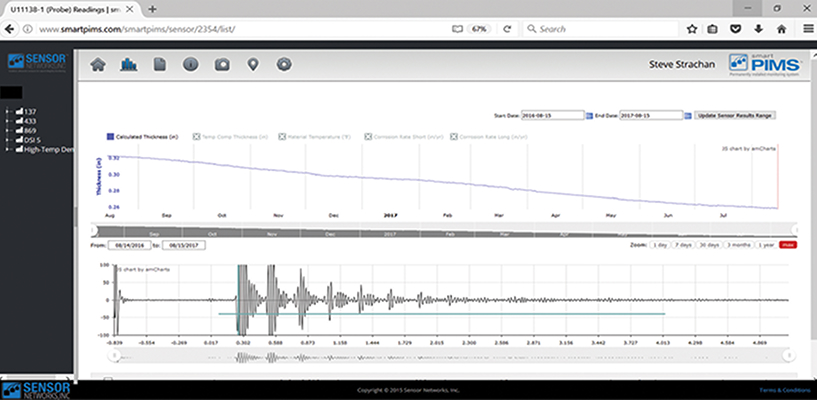

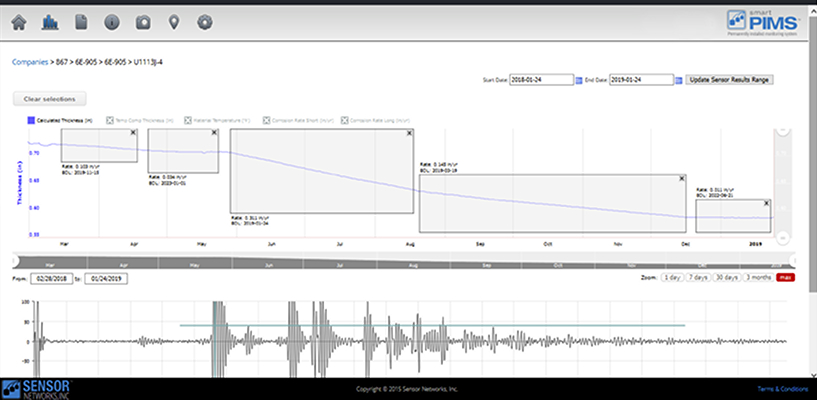

Trending screen graphically shows metal loss versus time, temperature, thickness, and digitized RF signals (A-Scans) for each measurement.

Features like temperature compensation help maximize the accuracy of thickness measurements.

Q&A

SNI's Permanently Installed UT Corrosion Monitoring Sensors combine the proven technique of Ultrasound Thickness Gauging with cutting-edge Internet of Things (IoT) technology. This enables continuous monitoring of wall thickness in critical infrastructure, providing real-time data on corrosion and erosion-related wall loss.

Both the SmartPIMS and MicroPIMS offer an ultra-high temperature option, featuring a single-element delay-line, designed for installation on surfaces with temperatures up to 500°C.

The SmartPIMS and MicroPIMS systems utilize a specialized epoxy as a couplant, effective for surface temperatures up to 80°C. Once cured, the epoxy remains in place, providing a permanent coupling between the sensor and the surface. For high-temperature applications, a malleable silver foil is used, clamped between the sensor and the surface. This silver foil ensures optimal contact for the proper propagation of ultrasound energy.

Request a Demo

Would love to see a demo? Share your contact details with us and our team will reach out to you shortly.