Background

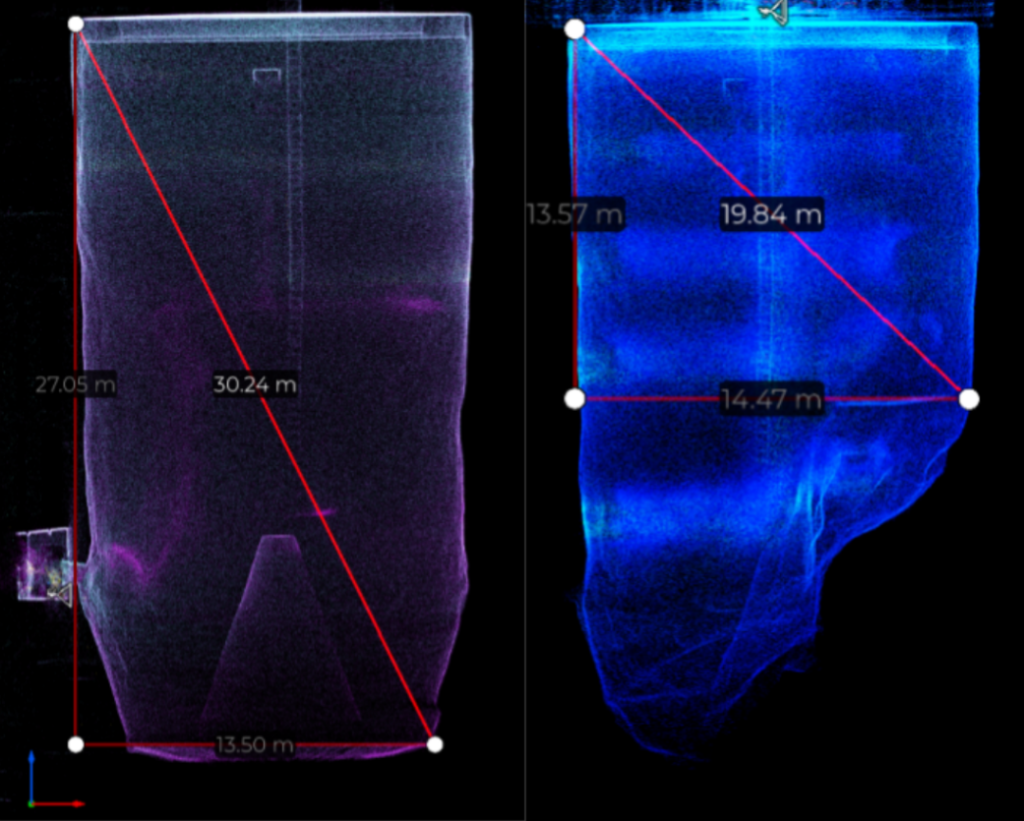

Silos are integral structures in the cement industry, designed for the storage of cement and other related materials. Typically cylindrical, these silos feature a hopper at the bottom for discharging the stored product into trucks for transport. Silos vary in size, with larger models reaching over 25 meters in height and more than 10 meters in diameter.

Accurate measurement of the contents within silos is crucial for effective stockpile inventory management. However, many plants still rely on manual measurement techniques that involve crude tools prone to significant error. Additionally, silos are confined spaces, making human entry not only cumbersome but also hazardous.

The Elios 3 with Surveying Payload

The Elios 3 drone is engineered for flight in GPS-denied environments, offering stable flight in confined spaces. Equipped with standard LiDAR, the system can be upgraded with a high-resolution LiDAR sensor capable of generating real-time, survey-grade 3D maps of the inspection area.

In silo applications, the combination of the Elios 3 and Surveying Payload provides a safe and efficient means of performing LiDAR scans inside silos, eliminating the need for manned entry. The resulting 3D map accurately represents the topography of the stockpile surface, enabling precise volumetric measurements of cement or other stored products.

Case Study: Proof-of Concept Volumetric Measurement of Cement in a Silo

Recently, the VISCOY field operations team conducted a proof-of-concept (POC) mission at a cement plant in our region. The goal was to assess the feasibility of using the Elios 3 with Surveying Payload to measure the volume of cement in one of the client’s silos.

The POC was carried out in two deployments:

- First Deployment: A 3D scan of the silo when it was empty, establishing the baseline volumetric capacity—i.e., the airspace volume within the silo.

- Second Deployment: A subsequent 3D scan of the silo filled with cement, enabling the determination of the reduced airspace volume due to the stored material.

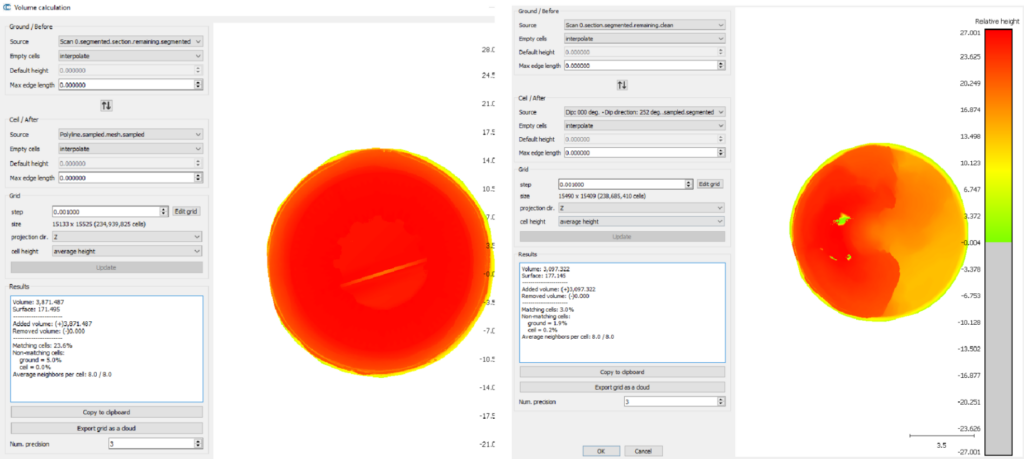

The cement volume was then calculated by subtracting the airspace volume of the silo filled with cement from the airspace volume of the empty silo.

Example Calculation:

- Airspace volume of empty silo: 3,871 m³

- Airspace volume of silo with cement: 3,097 m³

- Cement Volume = 3,871 m³ (empty) – 3,097 m³ (with cement) = 774 m³

The images below show the 3D model and airspace volume calculations for both the empty silo (left) and the silo filled with cement (right).

Each deployment/scan was completed in under an hour, and the total field deployment time for the POC took less than half a day. Post-flight processing of the 3D scan for volumetric analysis took less than two hours.

With the empty silo volume now recorded, subsequent measurements can be performed with a single scan of the silo, making future assessments both quicker and more accurate.

Conclusion

The use of the Elios 3 with Surveying Payload for volumetric measurements of cement stockpiles within silos offers several distinct advantages:

- Enhanced Safety: The drone eliminates the need for operators to enter confined spaces or work at heights, significantly reducing safety risks.

- Speed and Efficiency: Flights are quick and easy to perform, with accurate 3D scans completed in a single flight.

- Ease of Deployment: The system can be rapidly deployed as needed, with minimal preparation time.

- Increased Frequency of Inspections: Faster, safer inspections enable more frequent volumetric assessments, ensuring up-to-date inventory data.

- 3D Visualization and Repeatability: Real-time 3D mapping improves accuracy and allows for repeatable measurements with consistent comparability.

By leveraging drone technology for silo volumetric measurements, the cement industry can realize enhanced safety, operational efficiency, and more reliable inventory management.

Q&A

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.