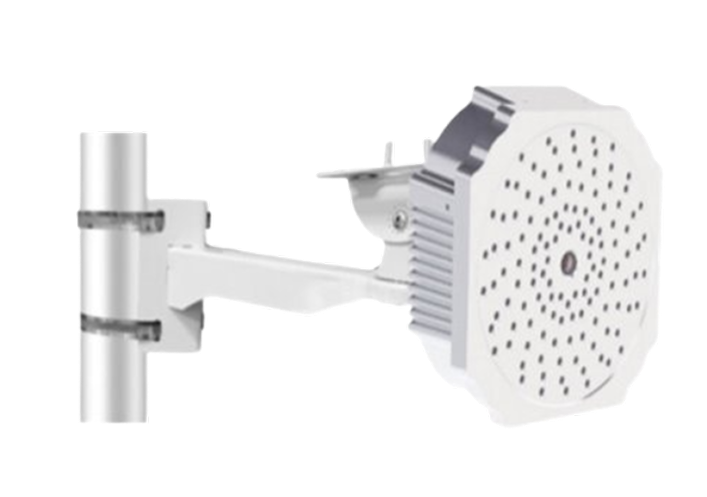

HZ-FA-371

Fixed Acoustic Imaging Camera

- 128 MEMS Microphones

- 2kHz ~ 65kHz detection

- Supports multiple source detection

- Real-time sound source localization

- Real-time partial discharge type prediction

- Real-time estimate gas leak rate

HZ-FA-371 Fixed Acoustic Imaging Camera

HZ-FA-371 is a high sensitivity acoustic imaging system specifically engineered for the detection of partial discharge issues in high-voltage electrical systems and gas leaks in compressed gas systems.

Boasting an array of 128 MEMS microphones, this sophisticated system excels in detecting and quantifying various instances of partial discharge while also providing accurate estimations of gas leak rates and associated costs.

Covering audible and ultrasonic frequencies from 2kHz to 65kHz, it facilitates precise sound source localization for advanced diagnostics.

With high performance design, FA371 supports 7*24h monitoring and can be installed on robot or any fixed place.

Voiceprint Features: A Fundamental Aspect of Industrial Monitoring

- In the realm of industrial operations, the subtle nuances of equipment sounds often hold the key to understanding their operational health. A device in its normal state emits specific, consistent sound characteristics that are unique to its design and function. These characteristics include energy levels, frequency, and periodicity, which remain relatively stable when the equipment is operating as intended. However, when a machine begins to degrade, malfunction, or encounter unusual conditions, its acoustic profile undergoes significant changes. These changes manifest in the form of irregularities in energy levels, disrupted periodicity, or the introduction of new frequency components that signal underlying issues.

- The ability to detect and interpret these acoustic variations is crucial for predictive maintenance and anomaly detection, enabling industries to prevent costly downtimes and extend equipment lifespan. Recognizing this potential, Hertzinno has pioneered innovative solutions that leverage advanced acoustic technology and artificial intelligence to monitor and analyze equipment sounds with unparalleled precision. Hertzinno’s suite of acoustic devices, including the cutting-edge acoustic camera and voiceprint equipment, represents a significant leap forward in industrial monitoring. These devices are designed to capture and interpret the intricate acoustic signatures of machinery, providing actionable insights into equipment health.

- The online acoustic camera, a standout product in Hertzinno’s portfolio, combines advanced sound localization technology with high-resolution imaging to pinpoint the source of unusual noises within a machine. This capability is particularly valuable in industries like power generation, where transformers and generators operate under immense stress, making them prone to failures. By identifying the exact location of abnormal sounds, the acoustic camera enables technicians to address issues before they escalate into major faults.

- Complementing the acoustic camera is Hertzinno’s voiceprint equipment, which specializes in capturing and analyzing the unique sound patterns emitted by machinery. These devices utilize voiceprint technology to record and store acoustic data, which is then subjected to sophisticated algorithms for detailed analysis. The process involves evaluating the sound data in both the time domain and frequency domain to extract meaningful characteristics that indicate equipment performance.

Power Industry

Ability to conduct early diagnosis and real-time monitoring through sound analysis, reducing equipment downtime, extending the life of devices, and lowering the costs and risks associated with manual inspections.

Factory Industry

Equipment such as pumps, compressors, and valves may experience mechanical faults or wear. Acoustic boxes can analyze the sounds produced by these devices, detecting abnormal noises like wear, looseness, or friction.

Mining & Oil Industry

In downhole operations, which often occur in complex environments, traditional monitoring methods may not fully assess the operational conditions. It can monitor the sounds produced by downhole equipment, such as gas pumps or oil extractors, helping identify abnormal sounds and ensuring operational safety and efficiency.

Detection of Gas Leaks:

Q&A

An acoustic camera is an imaging device used to locate and characterize sound sources. It consists of an array of microphones that simultaneously capture and process signals to create a representation of the sound source locations. This acoustic image is then overlaid in real time onto a digital camera image, enabling precise identification of the sound source.

Hertzinno’s acoustic camera, equipped with innovative architecture, AI-driven algorithms, and performance enhancements, is designed for a range of applications, including partial discharge detection, compressed gas leak detection, and mechanical fault identification.

The highly sensitive microphones of the Hertzinno Acoustic Camera can detect a broad range of acoustic frequencies, extending well beyond the audible spectrum. Hertzinno's AI-driven algorithm effectively filters out background noise, isolating ultrasound signatures associated with gas leaks or partial discharge.

The effective range of the Acoustic Camera depends on the frequency used for detection. For leak or partial discharge detection at a distance, the 10 to 30 kHz range is ideal. Higher frequency waves are more readily absorbed by the air, resulting in shorter detection ranges. To detect leaks over longer distances or partial discharge from high-voltage equipment outdoors, the camera should be tuned to lower frequencies, which can travel further.

Request a Demo

Would love to see a demo? Share your contact details with us and our team will reach out to you shortly.